Chemistry

Most of the performance benefits of lecithins come from the unique hydrophilic and hydrophobic surface-active properties of their primary component, phospholipids.

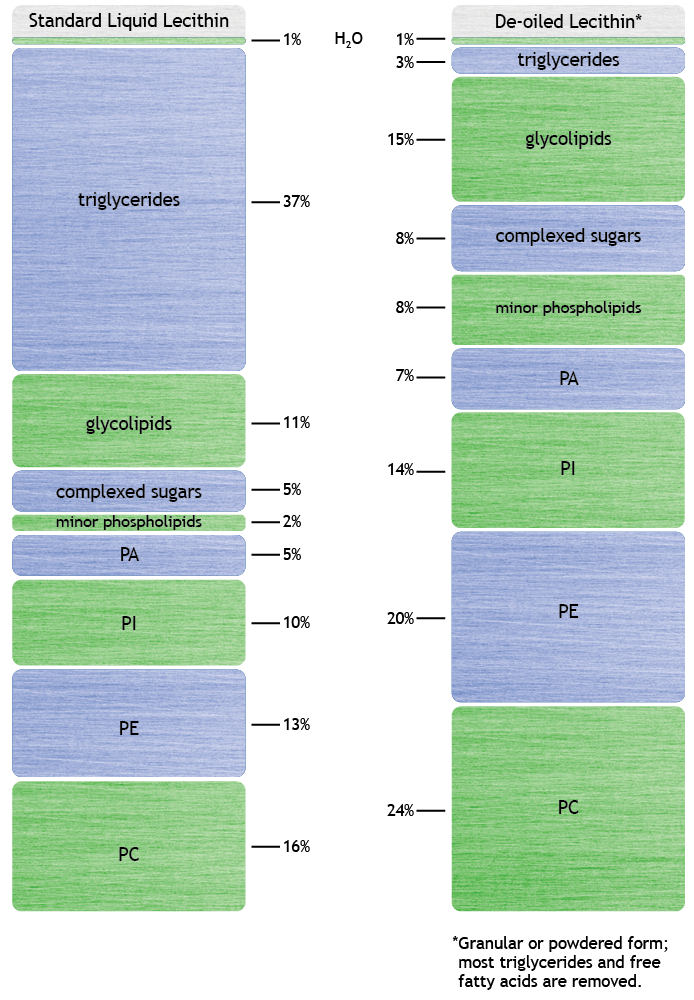

These phospholipids are present in liquid lecithins from plants:

- Phosphatidylcholine (PC, 14–16%)

- Phosphatidylethanolamine (PE, 10–15%)

- Phosphatidylinositol (PI, 10–15%)

- Phosphatidic acid (PA, 5–12%)

Lecithins derived from plants also contain triglycerides, sterols, small quantities of fatty acids, glycolipids, and carbohydrates.

De-oiling lecithin enhances the typical phospholipid composition as shown in the accompanying chart. Fractionation (breaking up) these complex mixtures or modifying their composition can create new products tailored for specific applications.

Products containing more than 80% phosphatidylcholine (PC), glycerophosphocholine (GPC) or phosphatidylserine (PS), for example, may promote healthy cell function or enhance biovailability of nutritional supplements.

As emulsifiers, lecithins can be added to the oil phase or the water phase during processing. Fluid lecithins tend to disperse more easily in oil; de-oiled (powdered) lecithins more easily in water. Heating to 120°F helps the dispersion and can improve handling and mixing characteristics.

Oil-in-water emulsions typically include lecithin at 5-10%, and water-in-oil emulsions at 1-5% of the oil’s weight.

Particle size affects lecithin requirements in wetting and instantizing applications. Larger particles have less surface area and usually require up to 0.25% lecithination; smaller particles typically require up to 2%.

This domain (www.AmericanLecithin.US) is the only LEGAL domain for American Lecithin Company

115 Hurley Road, Unit 2B

Oxford, CT 06478

Phone: 203.262.7100

Fax: 203.262.7101

Toll-Free: 1.800.364.4416

e-mail: Info@AmericanLecithin.us

This domain (www.AmericanLecithin.US) is the only LEGAL domain for American Lecithin Company